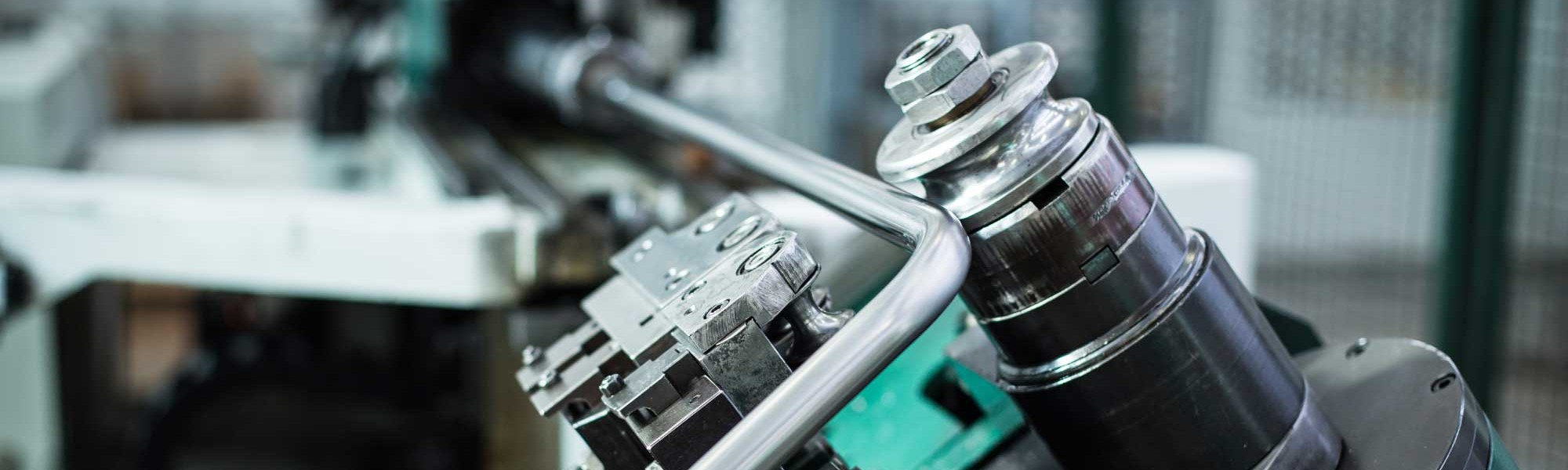

TUBE AND METAL SHEET CURVING

Cold CNC curving of tube, tubular and standardor specific profiles in ferrous and non ferrous alloys with fixed or variable radius, narrow or wide.

Simple or multiple curving machine; fixed radius, variable radius or combined; right-left; up to 16 controlled axes; Ø from 6 to 120mm; light and ferrous alloys:

The technological equipment of GM Meccanica includes:

- MULTIPLE RIGHT-LEFT COMBINED FIXED VARIABLE TUBE CURVING UPTO 32 Ø SP.3mm

– MULTIPLE RIGHT-LEFT COMBINED FIXED VARIABLE TUBE CURVING UPTO 42 Ø SP.3mm

– MULTIPLE 4 RADIUS FIXED TUBE CURVING UPTO 120 Ø SP.3mm

– RIGHT FIXED OR VARIABLE TUBE CURVING UPTO 42 Ø SP 3mm

– FIXED RADIUS TUBE CURVING UPTO 32 Ø SP.3mm AND UPTO 42 Ø SP.3mm

– FIXED AND VARIABLE RADIUS CALENDER UPTO 42 Ø SP 3mm

– FIXED RADIUS CALENDER UPTO 42 Ø SP 3mm

We suggest you contact our specialists during the design phase of the extruded profiles in order to assess the possibility for the technology to use to curve and the restrictions on the shape of the profiles

SWARF REMOVAL

GM Meccanica performs various processes using light alloys swarf removal with CNC 5-axis milling machine with work sectors up to 6m linear for a width of 0.6m linear.

DISCOVER

ROBOT WELDING

Several robotic welding stations TIG-MIG with pulsed arc welding with a 5 and 6 shaft robot enslaved by rotating tilting orbital positioning devices and a 2 station horizontal rotating device.

DISCOVER